Da Fan Qiao Village, Hong Shan Street, Xinwu District, Wuxi City, Jiangshu Province, China

86-13862257451

Da Fan Qiao Village, Hong Shan Street, Xinwu District, Wuxi City, Jiangshu Province, China

86-13862257451

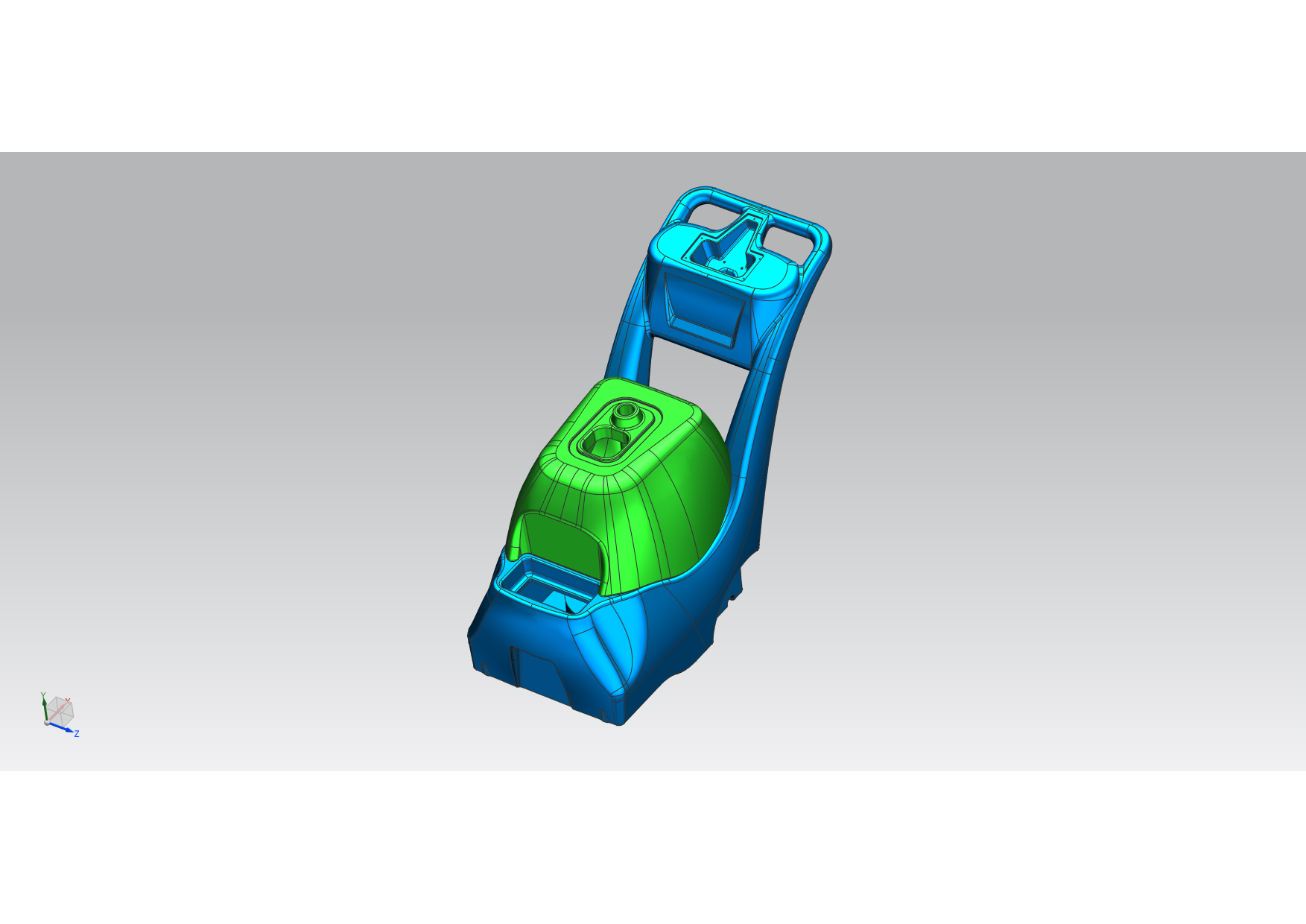

In today's fast-paced world, cleanliness is paramount, and vacuum cleaners have become an essential tool for maintaining a hygienic environment. However, the effectiveness of a vacuum cleaner largely depends on its design and functionality, which is where vacuum cleaner rotomolding moulds come into play. These moulds are used to manufacture vacuum cleaner components, such as dustbins, hoses, and nozzles, ensuring optimal performance and durability. In this article, we will explore the role of vacuum cleaner rotomolding mould wholesalers, factory direct sales, and China factory supply in providing high-quality products at affordable prices.

Vacuum cleaner rotomolding mould wholesalers play a crucial role in offering cost-effective solutions to manufacturers and retailers. By purchasing moulds in bulk, these wholesalers can negotiate lower prices from the manufacturers, passing on the savings to their customers. This not only helps businesses save money but also enables them to invest in other areas of their operations, such as marketing and product development.

Moreover, vacuum cleaner rotomolding mould wholesalers often offer a wide range of options, allowing businesses to choose the right mould for their specific needs. For instance, some moulds are designed for producing vacuum cleaners with advanced features, such as HEPA filters and adjustable suction power, while others are suitable for more basic models. By working with a reliable wholesaler, businesses can ensure they have access to the right tools to manufacture high-quality vacuum cleaners that meet consumer demands.

Factory direct sales provide another avenue for businesses to acquire vacuum cleaner rotomolding moulds at competitive prices. By cutting out intermediaries and dealing directly with the manufacturer, businesses can save on costs and receive faster delivery times. This is particularly beneficial for companies that require large quantities of moulds or need them urgently for production purposes.

In addition to cost savings and faster delivery times, factory direct sales often offer businesses the opportunity to customize their orders. Manufacturers can produce moulds in various sizes, materials, and colors to suit the specific needs of each customer. This level of flexibility allows businesses to create unique vacuum cleaner designs that stand out in the market and appeal to consumers.

When it comes to vacuum cleaner rotomolding moulds, China is widely regarded as a leading supplier due to its advanced manufacturing capabilities and competitive pricing. Chinese factories have invested heavily in technology and infrastructure, enabling them to produce high-quality moulds at a fraction of the cost compared to their Western counterparts. This has made Chinese-made moulds an attractive option for businesses looking to maximize their profits without compromising on quality.

Furthermore, China's strategic location and well-developed logistics network make it easier for businesses to import vacuum cleaner rotomolding moulds from Chinese factories. Companies can benefit from shorter lead times and reduced shipping costs, allowing them to quickly adapt to changing market demands and stay ahead of their competitors.

In conclusion, vacuum cleaner rotomolding moulds play a vital role in ensuring the effectiveness and durability of vacuum cleaners. By working with vacuum cleaner rotomolding mould wholesalers, taking advantage of factory direct sales, and sourcing from China factory supply, businesses can acquire high-quality moulds at affordable prices, ultimately benefiting both consumers and the industry as a whole. As the demand for innovative and efficient vacuum cleaners continues to grow, embracing these cost-effective solutions will be key to staying competitive in the market.